Maintenance and Care Considerations for a Mini Excavator

Regular Engine Inspection and Oil Management

For mini excavators, consistent engine inspection is crucial to maintain reliable operation. Gooddeer’s mini excavators are equipped with engines that require regular oil checks and timely changes. Monitoring oil levels and ensuring proper lubrication helps reduce wear on engine components and prevents potential breakdowns. Using high-quality oil recommended by the manufacturer and adhering to the maintenance schedule ensures smoother performance and longer engine life.

Hydraulic System Monitoring

The hydraulic system is central to the functioning of a mini excavator. Gooddeer’s models include precision hydraulic components that should be regularly checked for leaks, pressure consistency, and fluid levels. Maintaining clean hydraulic fluid and replacing filters at appropriate intervals ensures consistent operational efficiency. Any irregularities in hydraulic performance, such as slower response or unusual noises, should be addressed promptly to avoid damage to the system.

Track and Undercarriage Care

The tracks and undercarriage of a mini excavator experience significant stress during operation, especially on rough terrain. Gooddeer emphasizes regular cleaning and inspection of tracks to remove debris and prevent wear. Adjusting track tension according to manufacturer guidelines helps maintain optimal movement and stability. Regular checks can also identify early signs of wear on rollers, sprockets, and track links, reducing the risk of costly repairs.

Cooling System Maintenance

A reliable cooling system is essential to prevent engine overheating in mini excavators. Gooddeer’s mini excavators are equipped with efficient radiators and cooling components that should be inspected frequently. Ensuring the radiator is clean, coolant levels are sufficient, and hoses are intact contributes to maintaining optimal engine temperatures. Any blockage or leak in the cooling system should be addressed immediately to avoid engine damage.

Electrical System Checks

Mini excavators contain several electrical components, including the battery, control panels, and lighting systems. Regular inspection of wiring, connections, and battery condition is important for uninterrupted operation. Gooddeer recommends keeping electrical contacts clean and secure, and replacing worn components as needed. Proper electrical system maintenance prevents operational interruptions and supports reliable equipment performance.

Attachment and Bucket Inspection

The attachments and buckets of a mini excavator undergo significant stress during use. Gooddeer provides versatile attachments that require regular inspection for cracks, wear, and loose fasteners. Ensuring pins and bushings are lubricated and securely fastened maintains precision and safety during operation. Routine checks reduce the risk of mechanical failure and maintain efficiency in excavation tasks.

Proper Storage and Cleaning

Storing the mini excavator in a sheltered environment protects it from environmental elements that can accelerate wear and corrosion. Gooddeer recommends cleaning the machine after each use to remove dirt, mud, and debris that could affect moving parts. Regular cleaning combined with protective storage prolongs the lifespan of the excavator and reduces maintenance frequency.

Scheduled Professional Maintenance

In addition to daily and weekly inspections, periodic professional maintenance is important to sustain optimal performance. Gooddeer encourages following the service schedule provided by the manufacturer, including detailed checks of the engine, hydraulics, and other key systems. Professional servicing ensures that potential issues are detected early and that components are properly adjusted or replaced as necessary.

How to Choose the Right Mini Engineering Excavation Equipment

Understand Your Project Requirements

When selecting the right mini engineering excavation equipment, it's essential to understand the specific needs of your project. Gooddeer offers a range of mini excavators that can be tailored to different tasks, whether it’s digging, lifting, or precise trenching. The first step in choosing the right equipment is to evaluate the scope of the project, including the type of soil, depth of excavation, and the space available for maneuvering. For example, if you’re working in tight spaces or urban environments, a compact mini excavator would be more suitable. The mini excavators offered by Gooddeer are designed to operate efficiently in various environments, from construction sites to agricultural fields.

Machine Size and Weight

The size and weight of the mini excavator are crucial factors in determining its suitability for your project. A mini excavator that is too heavy might cause damage to the ground or structures in delicate environments, while one that is too light may not have enough power to handle the digging tasks. Gooddeer’s mini excavators come in different sizes and weights, allowing you to select the one that best fits your project’s needs. A smaller, lighter model may be ideal for residential or small construction tasks, while a heavier machine might be necessary for more intensive digging operations.

Engine Power and Performance

Another critical consideration when selecting mini engineering excavation equipment is the engine power and overall performance. Gooddeer offers mini excavators with varying horsepower levels that provide enough power for different tasks. The engine power determines the equipment’s ability to perform under different working conditions, such as in hard or rocky soil. For tasks that require continuous heavy-duty operation, opting for a model with higher horsepower ensures the machine can handle the demands of the job without overloading. At the same time, consider fuel efficiency as a factor, as it can impact long-term operational costs.

Hydraulic System and Attachments

The hydraulic system of an excavator plays a key role in its performance, especially in terms of lifting and digging efficiency. Gooddeer’s mini excavators come equipped with advanced hydraulic systems that deliver consistent power to the bucket and other attachments. When choosing a mini excavator, it is important to consider the types of attachments you will need for your tasks. Attachments like buckets, hammers, and augers add versatility to the machine and allow it to perform a range of functions beyond basic digging. Ensure that the machine you select is compatible with the attachments needed for your specific project.

Ease of Operation

For both novice and experienced operators, ease of operation is an important factor in selecting mini excavation equipment. Gooddeer’s mini excavators are designed with user-friendly controls and ergonomic designs to improve operator comfort and productivity. The ability to operate the equipment with minimal training can reduce downtime and ensure tasks are completed efficiently. Look for models with intuitive controls, adjustable seats, and good visibility, as these features make operation smoother and more efficient, even in confined spaces.

Maintenance and Serviceability

Regular maintenance is essential for keeping mini excavators in good working condition, and selecting equipment that is easy to maintain can save both time and money. Gooddeer’s mini excavators are built with durability in mind, but it’s also important to choose models that offer easy access to key components such as filters, hoses, and oil levels for regular servicing. When evaluating different machines, consider how easily maintenance tasks can be carried out, whether you can perform routine checks yourself, and the availability of spare parts and service centers. Choosing equipment with straightforward maintenance routines helps extend the lifespan of the machine and reduces the risk of unexpected repairs.

Budget and Cost-Effectiveness

The cost of purchasing or renting mini engineering excavation equipment is another critical consideration. While it may be tempting to opt for the cheapest option, it’s important to weigh the cost against the benefits and the specific requirements of your project. Gooddeer offers competitive pricing on mini excavators, ensuring you get value for money while still meeting the demands of your job. It’s essential to consider not only the initial purchase price but also the long-term costs associated with fuel, maintenance, and potential repairs. In many cases, investing in higher-quality equipment may result in lower maintenance costs and improved efficiency over time.

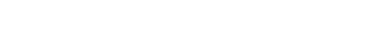

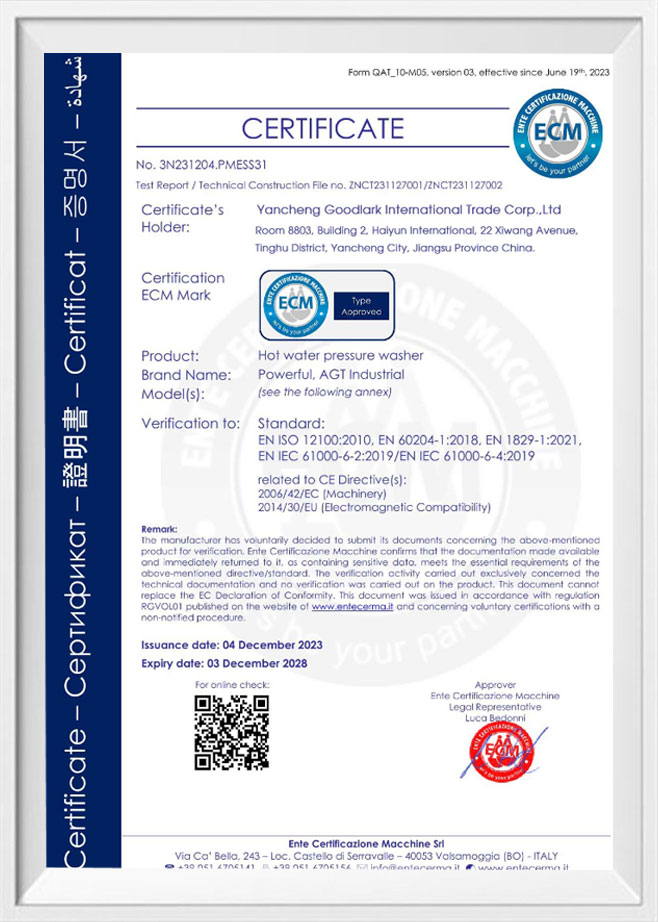

Safety Features and Certifications

Safety should always be a top priority when operating mini excavators. Look for equipment that is equipped with safety features such as rollover protection, stability control systems, and emergency stop functions. Gooddeer’s mini excavators come with built-in safety features that help protect operators and prevent accidents on the job site. Additionally, ensure that the equipment meets industry safety standards and certifications. Machines that comply with safety regulations are less likely to encounter operational issues and are a safer option for the operator.