What Types of Air Compressors Are Available and What Applications Are They Suitable For?

Introduction to Air Compressors

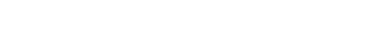

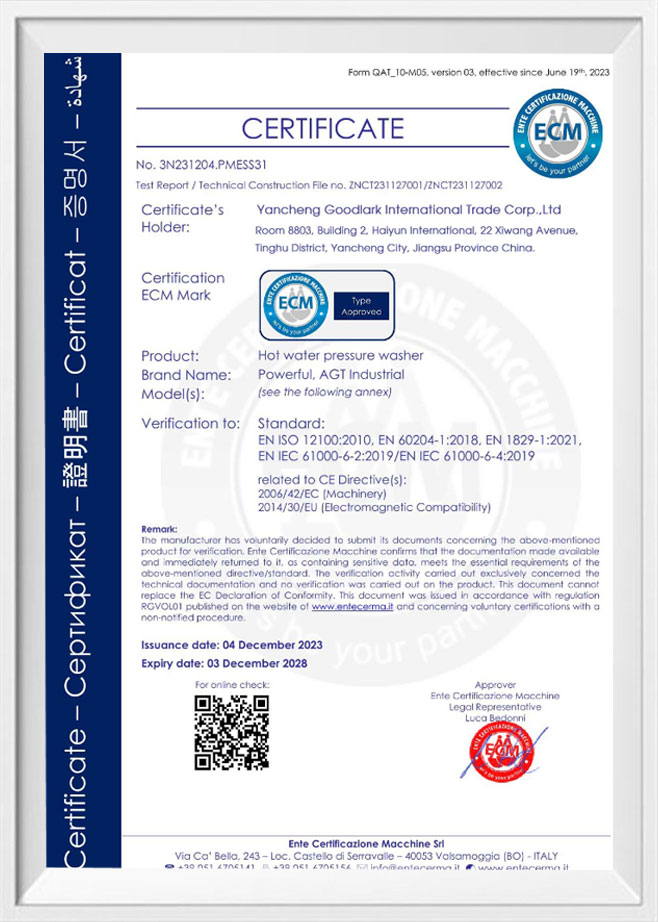

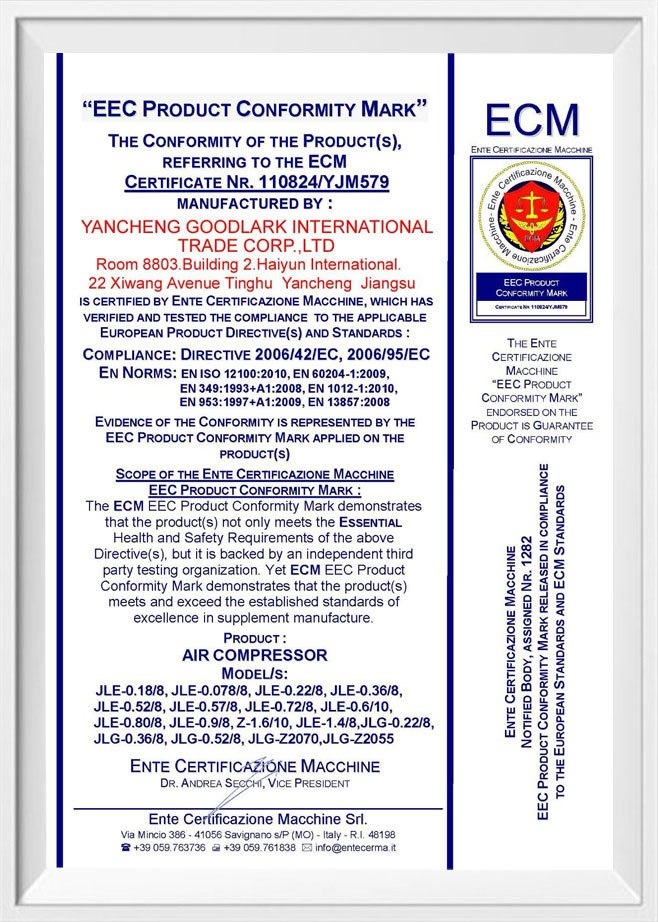

Air compressors are essential pieces of machinery used in a wide range of industries, from manufacturing to agriculture. They work by converting power into potential energy stored in compressed air, which can then be used to power various tools and equipment. At Gooddeer, an industrial and trade enterprise committed to providing high-quality mechanical products, we offer a variety of air compressors designed to meet the needs of industrial production, agricultural operations, and construction.

Reciprocating Air Compressors

Reciprocating air compressors are one of the most commonly used types of compressors. These machines use a piston-driven mechanism to compress air within a cylinder. As the piston moves up and down, it draws in air and then compresses it to a higher pressure, storing the air in a tank. Reciprocating compressors are typically available in single-stage or multi-stage versions, depending on the pressure requirements.

These compressors are widely used in various applications, particularly in industries where high pressure is required. They are commonly found in manufacturing plants, automotive repair shops, and construction sites. Their compact design and ability to deliver high-pressure air make them suitable for powering pneumatic tools, spray painting equipment, and other industrial machinery. Additionally, they are used in agricultural operations to power irrigation systems, crop spraying equipment, and air-driven pumps. At Gooddeer, we provide reciprocating air compressors that offer reliable performance for both small and large-scale applications.

Screw Air Compressors

Screw air compressors use a pair of interlocking rotors to compress the air. As the rotors rotate, they trap air and reduce its volume, increasing the pressure. These compressors are known for their efficiency and continuous operation, making them ideal for applications where a constant air supply is needed. Unlike reciprocating compressors, screw compressors are typically oil-injected, which helps to lubricate the internal components and reduce wear over time.

Screw compressors are commonly used in industrial settings where a continuous supply of compressed air is needed for operations like manufacturing, packaging, and automation. They are also widely used in large-scale operations such as refineries, petrochemical plants, and food processing plants. Their reliability and ability to handle high-volume air demands make them a top choice for industries requiring large air compressors for production processes. Gooddeer’s screw air compressors are designed to deliver consistent and efficient performance for long-term operations in demanding environments.

Rotary Vane Compressors

Rotary vane compressors operate by using a rotor with a series of blades that slide in and out of slots, trapping and compressing air as it rotates. These compressors are quieter and produce less vibration compared to other types, making them ideal for applications that require a more stable and noise-reduced environment. Rotary vane compressors are often used in industries where high precision is required, such as laboratory work, medical facilities, and small workshops.

In addition to these applications, rotary vane compressors are commonly used for powering pneumatic equipment, HVAC systems, and smaller tools. Their relatively simple design and low maintenance requirements make them an attractive option for smaller-scale applications. Gooddeer offers rotary vane compressors that are well-suited for operations where quieter, more reliable performance is needed, while still providing high-quality air pressure for various applications.

Centrifugal Air Compressors

Centrifugal air compressors operate based on the principle of centrifugal force. These compressors use a rapidly rotating impeller to accelerate air, and then slow it down through a diffuser to increase its pressure. They are capable of producing very high volumes of compressed air, which makes them suitable for large-scale industrial applications that require a steady and continuous airflow.

Centrifugal compressors are commonly used in large manufacturing plants, oil refineries, chemical industries, and power generation facilities. They are ideal for applications where large amounts of compressed air are required for processes such as cooling, cleaning, and powering industrial machinery. Although centrifugal compressors are typically more expensive and complex than other types, their ability to deliver a constant, high-flow air supply makes them essential for high-demand operations. Gooddeer’s range of centrifugal compressors meets the needs of large industrial sectors that require continuous, high-pressure airflow.

Portable Air Compressors

Portable air compressors are smaller, mobile units designed to provide compressed air for various tasks on construction sites, agricultural operations, and even remote locations. These compressors are typically powered by gasoline or diesel engines, making them ideal for areas without a reliable electrical supply. Portable compressors are widely used in industries such as construction, mining, and road work, where mobility and versatility are essential.

These compressors are perfect for powering tools such as jackhammers, nail guns, air-driven drills, and paint sprayers. Their lightweight and compact design allow operators to transport them easily between different work sites, making them a valuable asset for construction crews and agricultural workers. Gooddeer offers portable air compressors designed to withstand the rigors of fieldwork, providing dependable air power wherever it is needed.

Applications of Air Compressors in Different Industries

Air compressors are used across a wide range of industries, each with specific requirements for compressed air. The table below summarizes the types of air compressors and their typical applications in various sectors:

| Type of Compressor |

Applications |

| Reciprocating Air Compressors |

Automotive repair, construction sites, agricultural operations, pneumatic tools, spray painting |

| Screw Air Compressors |

Manufacturing, packaging, automation, refineries, petrochemical plants, food processing |

| Rotary Vane Compressors |

Laboratories, medical facilities, smaller workshops, HVAC systems, pneumatic equipment |

| Centrifugal Air Compressors |

Large manufacturing plants, oil refineries, chemical industries, power generation, high-volume air demand |

| Portable Air Compressors |

Construction sites, mining operations, road work, fieldwork, portable tools |

Choosing the Right Air Compressor for Your Needs

Choosing the right air compressor depends on several factors, including the volume of air required, the level of pressure needed, and the specific tasks to be performed. For smaller tasks, such as powering pneumatic hand tools or inflating tires, a portable or reciprocating compressor may be sufficient. However, for large-scale operations that require continuous airflow or high-pressure output, screw or centrifugal compressors may be more suitable. It is important to assess the specific needs of your operation to ensure that you choose the right compressor for the job.

At Gooddeer, we offer a wide range of air compressors tailored to meet the specific requirements of different industries. Whether you're in construction, agriculture, or manufacturing, we provide high-quality air compressors that offer reliability, efficiency, and long-term performance. Our expert team is always available to assist you in selecting the right compressor for your needs, ensuring that your operations run smoothly and efficiently.

FAQ

Q: How often should I perform maintenance on my air compressor?

A: Regular maintenance is crucial to ensure the optimal performance of your air compressor. It is recommended to check and replace the oil every 100-300 hours of operation, depending on the model. Additionally, air filters should be cleaned or replaced regularly, and the compressor's belts should be inspected for wear. It's also important to check for any leaks, ensure the system's pressure is within the recommended range, and conduct a general inspection at least every 6 months to maintain the equipment's efficiency.

Q: What is the lifespan of an air compressor?

A: The lifespan of an air compressor largely depends on its type, maintenance, and usage. On average, with proper maintenance, a well-maintained air compressor can last between 10 to 15 years. However, regular servicing, cleaning, and prompt repairs can extend its lifespan. Overloading or neglecting maintenance may reduce the operational life of the compressor.

Q: Why is my air compressor overheating?

A: Overheating in an air compressor can be caused by several factors. The most common reasons include insufficient ventilation, dirty air filters, or a malfunctioning cooling system. If the oil level is too low or the oil is too old, it can also cause the compressor to overheat. It's important to regularly check the oil and ensure the compressor has adequate airflow to prevent overheating. If these issues persist, it's best to consult with a technician to ensure proper function.

Q: How can I reduce noise levels from my air compressor?

A: Air compressors, especially larger models, can generate significant noise during operation. To reduce noise, consider placing the compressor on vibration-dampening pads or using noise-reducing enclosures. Additionally, ensure that the compressor is well-maintained, as worn-out parts or low oil levels can contribute to excessive noise. Using quieter compressor models, such as rotary screw compressors, can also help minimize noise levels.

Q: What are the signs that my air compressor needs repairs?

A: Common signs that an air compressor may need repairs include unusual noises (such as grinding or rattling), decreased pressure output, frequent cycling on and off, or failure to start. Additionally, if there are visible oil leaks, increased vibration, or the compressor is overheating regularly, it may indicate a problem. Timely repairs and maintenance can prevent further damage and ensure the compressor continues to operate efficiently.

Q: Can I use my air compressor for multiple tools at once?

A: Yes, you can use your air compressor for multiple tools at once, as long as the compressor's capacity is sufficient to meet the demand of all tools simultaneously. It's important to check the compressor's specifications to ensure that it can handle the required pressure and airflow for the tools you intend to use. Overloading the compressor can lead to inefficiency or damage, so it’s always best to match the compressor's output with your needs.

Q: How can I improve the energy efficiency of my air compressor?

A: Improving the energy efficiency of an air compressor can be achieved by performing regular maintenance, such as ensuring proper lubrication, checking for air leaks, and replacing worn parts. Upgrading to energy-efficient models, such as variable speed compressors, can also reduce energy consumption. Additionally, using a compressor that matches the specific needs of your operation and turning off the compressor when not in use can help save energy.

Q: Can I store my air compressor outdoors?

A: Storing an air compressor outdoors is not ideal, as exposure to the elements can cause rust, damage to electrical components, and reduced performance. If outdoor storage is necessary, make sure the compressor is properly covered with a weather-resistant tarp or enclosure to protect it from rain, snow, or direct sunlight. It's also important to periodically inspect the compressor for any signs of damage or wear caused by environmental factors.