How Construction Engineering Equipment Can Improve Construction Efficiency and Reduce Costs

Introduction to Construction Engineering Equipment

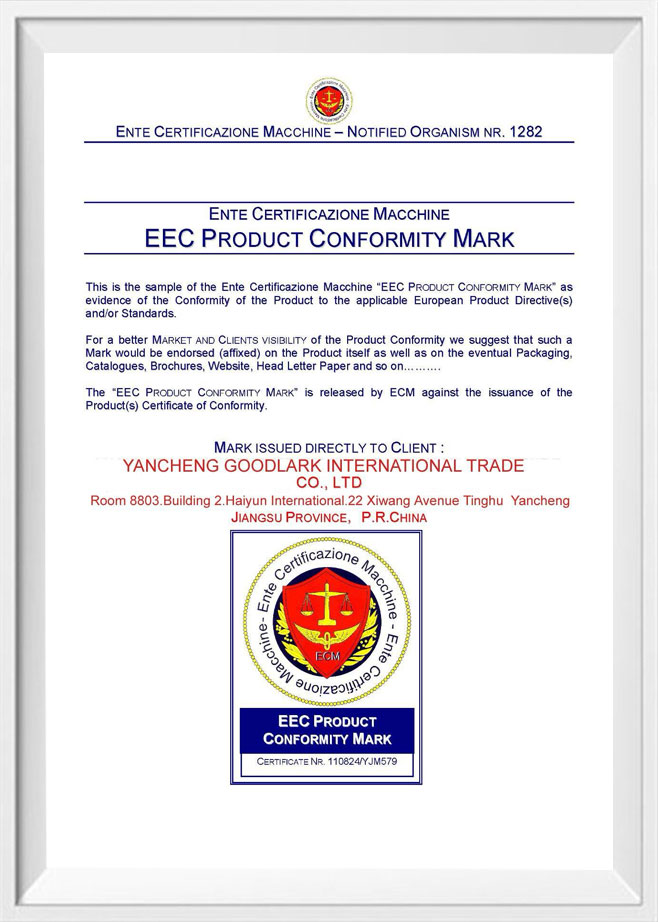

Construction engineering equipment plays a pivotal role in enhancing the efficiency of construction projects and reducing overall costs. The right machinery and tools not only improve the speed of operations but also optimize resource usage, ensuring that projects are completed on time and within budget. Companies like Gooddeer, which specialize in industrial and trade sectors, provide a wide range of mechanical products, including construction equipment such as air compressors, agricultural machinery, and small engineering machinery, that help boost productivity and reduce costs in construction operations.

Improved Productivity through Specialized Machinery

Specialized construction engineering equipment is designed to perform specific tasks quickly and efficiently, which significantly increases productivity. For instance, machinery such as earth movers, cranes, and excavators are crucial in handling large-scale construction tasks like digging, lifting, and transporting materials. By utilizing equipment designed for specific applications, workers can complete tasks in a fraction of the time it would take manually, allowing construction projects to progress faster.

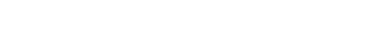

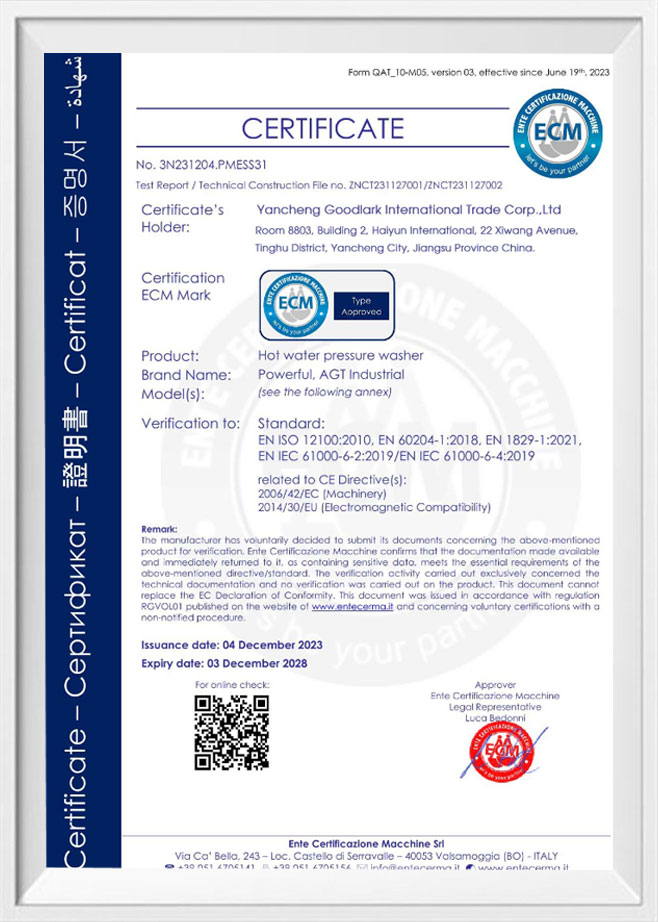

For example, air compressors, which are often part of construction fleets, help power various pneumatic tools, including drills, hammers, and impact wrenches. These machines are essential for tasks that require high torque and force, reducing the amount of manual labor required and speeding up the completion of certain tasks. This improvement in productivity can significantly contribute to meeting project deadlines and maintaining a high work pace on-site.

Cost Reduction through Efficient Resource Management

Construction projects often face cost overruns due to inefficiencies in resource allocation. The use of advanced construction equipment helps to optimize resource management by reducing waste and improving overall project workflow. Equipment like forklifts, concrete mixers, and bulldozers ensures that materials are used efficiently, reducing wastage and ensuring that only the necessary amount of materials is ordered and used.

Moreover, the use of machinery that is energy-efficient and requires minimal maintenance also helps lower operational costs over the long term. Gooddeer’s offering of high-quality machinery and equipment, such as air compressors and small engineering machinery, is particularly beneficial in this regard. These tools ensure that operations are not only effective but also cost-efficient, thus reducing the overall cost of construction operations.

Safety Enhancements Leading to Reduced Costs

Construction sites are inherently risky environments, and accidents can lead to costly delays, medical expenses, and legal issues. Construction engineering equipment helps mitigate these risks by enabling safer working conditions. For instance, cranes and excavators allow for the lifting and moving of heavy materials without the need for manual labor, reducing the likelihood of worker injuries.

Additionally, modern machinery is equipped with advanced safety features such as automatic shutoff systems, emergency alarms, and safety sensors. These features help prevent accidents and damage to equipment, ultimately reducing the costs associated with repairs, insurance, and worker compensation. By investing in high-quality, reliable machinery, construction companies can significantly improve safety on-site, leading to fewer accidents and lower associated costs.

Enhanced Precision and Quality of Work

Construction engineering equipment not only increases efficiency but also enhances the quality of work. For example, precision machinery such as leveling equipment and automated surveying tools ensures that construction projects are completed with high levels of accuracy. This reduces the need for costly rework or corrections due to errors that could otherwise arise from manual measurements or operations.

Small engineering machinery and accessories, such as compactors and vibrators, help ensure the foundation and structure of buildings are solid and well-built, preventing future structural issues. In the long run, ensuring the accuracy and quality of the initial construction phase can prevent costly repairs and maintenance after the project is completed, which leads to overall cost savings.

Time Savings through Automation and Efficiency

Automation is another key factor in improving construction efficiency. Modern construction engineering equipment is often equipped with automated controls that streamline processes and reduce human error. For example, automated concrete mixers ensure that the right proportions of materials are used, leading to consistent quality and faster project completion. Similarly, robotic machinery for tasks such as bricklaying and welding helps speed up construction without compromising quality.

By integrating automation into construction operations, companies can cut down on labor costs, reduce the time required to complete projects, and improve the overall efficiency of the construction process. Gooddeer’s diverse range of small engineering machinery is well-suited to these types of automated operations, enhancing efficiency and helping to reduce time-related costs.

Cost Comparison of Manual vs. Equipment-Driven Construction

While manual labor is still essential in certain areas of construction, the costs associated with human labor often outweigh those of using machinery. For instance, workers may require longer hours to complete tasks manually, which leads to increased labor costs, longer project durations, and the potential for higher error rates. In contrast, utilizing construction equipment like air compressors or excavators enables faster completion of tasks with less manpower, ultimately saving both time and money.

The table below highlights a cost comparison between manual labor and the use of construction equipment, illustrating how machinery can help reduce construction expenses:

| Task |

Manual Labor Cost |

Equipment Cost |

| Excavation |

High (requires several workers over extended periods) |

Low (excavators complete work faster with minimal labor) |

| Material Lifting |

High (requires cranes or multiple workers for lifting) |

Low (cranes lift materials quickly and safely) |

| Concrete Mixing |

High (manual mixing is time-consuming and requires workers) |

Low (automated mixers ensure consistency and speed) |

| Site Cleanup |

High (manual labor for sweeping and clearing debris) |

Low (machines can clear debris quickly and efficiently) |

Long-Term Benefits of Investing in Construction Equipment

While the initial investment in construction engineering equipment may seem high, the long-term benefits far outweigh the costs. Reliable equipment not only improves efficiency and safety but also reduces operational costs and enhances the overall quality of work. Over time, the return on investment (ROI) from using high-quality machinery like air compressors and small engineering machinery becomes apparent in the form of reduced project timelines, lower labor costs, and fewer maintenance issues.

Moreover, the increased precision and reliability of equipment reduce the likelihood of costly errors and delays, further contributing to cost savings. For companies like Gooddeer, which focus on providing high-quality mechanical products, the integration of durable and efficient equipment into construction operations results in long-term cost reduction and a more streamlined construction process.

What Are the Safety Precautions for Operating Agricultural Tillage Equipment?

Introduction to Agricultural Tillage Equipment

Agricultural tillage equipment plays a vital role in preparing the soil for planting by breaking up compacted soil and promoting better root growth. These machines are essential in modern farming and come in various forms such as plows, harrows, and cultivators. Given the power and complexity of these machines, it is crucial to adhere to strict safety protocols to ensure the safety of operators and those working around the equipment. Gooddeer, as an industrial and trade enterprise focused on providing high-quality mechanical products like agricultural machinery, recognizes the importance of safety in agricultural operations.

Pre-Operation Safety Checks

Before operating any agricultural tillage equipment, it is essential to perform thorough pre-operation safety checks. These checks ensure that the machinery is in good working condition and that any potential issues are addressed before use. Operators should inspect the equipment for signs of wear or damage, especially in key areas like the blades, hydraulic systems, and tires. It is also important to check the fuel levels and ensure that all connections are secure.

For equipment like tillers and plows, operators should ensure that the safety guards and shields are in place and functioning properly. These safety features are designed to prevent debris from being thrown from the machinery, which can cause injury to the operator or nearby workers. Additionally, operators should ensure that all bolts, nuts, and other fasteners are tightened to prevent any parts from loosening during operation. Gooddeer's commitment to providing quality machinery means that their products come with thorough user manuals that guide operators on how to conduct these essential checks.

Proper Operator Training

One of the most important safety precautions when operating agricultural tillage equipment is ensuring that the operator is properly trained. Proper training not only helps the operator understand how to use the equipment effectively but also teaches them how to recognize and avoid potential hazards. Operators should be familiar with the equipment’s controls, including how to start and stop the machine, engage the tilling mechanism, and operate the equipment in different soil conditions.

In addition to training on operating the machinery, it is equally important for operators to be familiar with the safety features of the equipment. This includes knowing the location and proper use of emergency shutoff switches, safety locks, and warning signals. At Gooddeer, the company ensures that all users are provided with the necessary guidance and support to safely operate machinery like tillers and plows, reducing the risk of accidents on the farm.

Personal Protective Equipment (PPE)

Personal protective equipment (PPE) is essential when operating agricultural tillage equipment to protect against potential hazards. Operators should wear the appropriate PPE, which typically includes heavy-duty gloves, safety boots with steel toe caps, ear protection, and eye protection such as goggles. In addition, depending on the environment, dust masks may be necessary to protect against inhaling harmful dust particles generated by the tillage equipment.

Wearing PPE helps reduce the risk of injury in case of equipment malfunction or unexpected debris. Additionally, ear protection is particularly important when operating machines like tractors or plows, which can generate high levels of noise. At Gooddeer, operators are encouraged to invest in PPE that is suitable for their specific machinery to ensure optimal safety during operation.

Safe Operating Practices

While proper equipment and training are crucial, adhering to safe operating practices is just as important when using agricultural tillage equipment. Operators should always follow the manufacturer’s guidelines for operating the machinery. For example, they should avoid making sharp turns or operating the equipment on uneven terrain unless the equipment is designed for such conditions. This helps prevent tip-over accidents and ensures the equipment functions efficiently.

Additionally, operators should avoid overloading the equipment, as this can cause mechanical failures or accidents. When working in areas with high traffic or near other workers, operators should maintain a safe distance from others and use appropriate warning signals. It is also recommended to avoid working in adverse weather conditions such as rain, snow, or extreme heat, as these can reduce the equipment’s performance and increase the risk of accidents. Gooddeer’s machinery is designed with safety in mind, but operators must also be vigilant in adhering to safety protocols.

Regular Maintenance and Inspections

Regular maintenance and inspections are critical to the safe operation of agricultural tillage equipment. Keeping the equipment in good working condition ensures that it operates smoothly and reduces the likelihood of accidents caused by mechanical failure. Operators should follow the manufacturer's recommendations for routine maintenance, such as changing oil, replacing filters, and inspecting hydraulic systems.

It is also important to clean the equipment after each use to prevent soil and debris buildup, which can cause mechanical issues or hinder the performance of the tilling equipment. Scheduled inspections should be conducted by a qualified technician to identify any underlying issues that might not be visible to the operator. Gooddeer provides after-sales services, including maintenance and repair, to ensure the longevity and safe operation of agricultural machinery.

Emergency Procedures

Even with proper safety precautions in place, accidents can still happen. Therefore, operators must be trained in emergency procedures in case of a malfunction or unexpected situation. Knowing how to shut down the equipment quickly and safely is essential. Operators should also be familiar with the procedures for dealing with common emergencies, such as equipment fires, hydraulic failures, or if the equipment gets stuck in the soil.

In the event of an emergency, it is crucial to have a clear and established plan in place. Operators should know the location of fire extinguishers and first aid kits and should ensure that they are easily accessible. Gooddeer emphasizes the importance of safety preparedness and provides safety manuals with all of its machinery to help operators respond effectively in emergencies.

Cost Comparison of Safe vs. Unsafe Operations

The table below compares the potential costs of safe operations versus unsafe operations when using agricultural tillage equipment:

| Aspect |

Safe Operations |

Unsafe Operations |

| Maintenance Costs |

Low (regular maintenance prevents issues) |

High (neglecting maintenance leads to breakdowns) |

| Operator Health and Safety |

Improved (PPE reduces risk of injury) |

Increased risk of injury (lack of PPE and training) |

| Equipment Longevity |

Longer lifespan (proper care and operation) |

Shortened lifespan (overloading and misuse) |

| Legal and Insurance Costs |

Low (adherence to safety standards reduces liability) |

High (accidents lead to lawsuits and insurance claims) |