What Are the Main Advantages and Disadvantages of a Piston Air Compressor?

Introduction to Piston Air Compressors

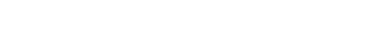

Piston air compressors, also known as reciprocating compressors, are widely used in various industries for their efficiency in converting power into compressed air. These compressors function by using a piston inside a cylinder, which moves back and forth to compress air. At Gooddeer, we offer a range of mechanical products, including piston air compressors, that are used in industrial production, agricultural operations, and construction.

Advantages of Piston Air Compressors

High Pressure Output

One of the key advantages of piston air compressors is their ability to produce high-pressure air. They are particularly effective for applications that require higher pressure levels, such as powering pneumatic tools, spray painting equipment, or industrial machinery. The ability to compress air to higher pressures makes them ideal for industries like automotive, construction, and manufacturing. Gooddeer’s piston air compressors are designed to provide reliable and consistent high-pressure output, making them suitable for a wide range of tasks that demand strong air pressure.

Compact and Portable Design

Piston air compressors are generally more compact and portable compared to other types of compressors, such as screw or centrifugal models. This makes them a popular choice for small to medium-sized operations where space is limited or mobility is important. The relatively small size allows for easy transportation between different job sites, making them ideal for fieldwork in construction and agriculture. At Gooddeer, we provide piston air compressors that are not only efficient but also easy to move around, which is particularly beneficial in industries requiring mobility and flexibility.

Simple Design and Maintenance

The design of piston air compressors is relatively simple and straightforward, which makes them easy to operate and maintain. Their mechanical components, such as pistons, cylinders, and valves, are easy to access and service, making regular maintenance more manageable. For industries like agriculture and construction, where downtime can result in significant losses, this simplicity reduces the likelihood of prolonged maintenance periods. By following routine maintenance schedules, piston air compressors can operate efficiently for many years with minimal issues.

Cost-Effective for Small to Medium-Scale Operations

Another significant advantage of piston air compressors is their affordability, especially for small to medium-scale operations. These compressors are often less expensive than more complex alternatives like screw or centrifugal compressors. This makes them an attractive choice for smaller businesses or those just starting out. Whether for agricultural use, powering small machinery, or running a limited set of pneumatic tools, piston air compressors offer a cost-effective solution without compromising on performance. Gooddeer ensures that all its piston air compressors are competitively priced, making them a valuable option for businesses looking to maximize their investment in air compressor technology.

Disadvantages of Piston Air Compressors

Limited Continuous Operation

One of the primary disadvantages of piston air compressors is their inability to operate continuously without rest. The piston-driven mechanism generates heat and requires regular cooling periods to avoid overheating and damage to the components. Unlike screw compressors, which can operate continuously, piston air compressors are more suited for intermittent use, where the equipment is used in bursts rather than for extended periods. This limitation can affect productivity in large-scale operations that require constant airflow or air pressure, such as large manufacturing plants. In such cases, a screw or centrifugal compressor may be more appropriate.

Higher Noise Levels

Piston air compressors tend to generate higher noise levels compared to other compressor types, such as rotary screw or centrifugal compressors. The back-and-forth motion of the piston creates vibrations and noise, which can be disruptive in environments where noise reduction is a priority, such as in workshops or hospitals. The noise generated by piston compressors may require additional noise-reduction measures, such as placing the equipment in soundproof enclosures or using ear protection for workers. Gooddeer’s piston air compressors are designed with durability in mind, but it’s important to consider noise levels when planning their use in noise-sensitive environments.

Limited Efficiency at Higher Air Demands

While piston air compressors are effective for high-pressure applications, they are less efficient when it comes to high-volume, continuous air supply needs. As the demand for compressed air increases, piston compressors may experience a drop in efficiency, leading to increased energy consumption. For industries with high and consistent air demand, such as large-scale manufacturing or automotive production, piston air compressors may not be the most efficient choice. In such cases, other compressors like rotary screw compressors, which are designed to handle continuous, high-volume airflow, may be more suitable.

Wear and Tear Over Time

Due to the mechanical nature of piston air compressors, they experience wear and tear over time, particularly on components such as pistons, rings, and valves. While these parts can be replaced, the frequency of maintenance and part replacements can add to the overall operational costs. Additionally, worn-out components can lead to reduced efficiency and potential breakdowns, resulting in unplanned downtime. Regular maintenance and timely replacement of parts are necessary to minimize these issues and extend the lifespan of the compressor. Gooddeer’s piston air compressors are designed to offer long-lasting performance, but understanding the need for regular servicing is important for maintaining efficiency.

Cost Comparison: Piston vs. Other Compressors

The table below provides a comparison of the advantages and disadvantages of piston air compressors in relation to other types of compressors, highlighting their respective applications and suitability for various industries:

| Type of Compressor |

Advantages |

Disadvantages |

| Piston Air Compressors |

High pressure output, compact design, cost-effective, easy maintenance |

Limited continuous operation, higher noise levels, wear and tear, less efficient at high air demands |

| Screw Compressors |

Continuous operation, quieter, more energy-efficient, long lifespan |

Higher initial cost, complex design, larger size |

| Centrifugal Compressors |

High volume air supply, reliable for large-scale operations |

Expensive, complex, not suitable for small-scale operations |

How to Choose the Right Reciprocating Air Compressor?

Introduction to Reciprocating Air Compressors

Reciprocating air compressors are widely used in various industries due to their reliable performance and efficiency in converting mechanical energy into compressed air. These compressors use a piston inside a cylinder to compress air, making them ideal for applications that require higher pressure. At Gooddeer, we provide high-quality reciprocating air compressors that serve a variety of industrial, agricultural, and construction purposes. Choosing the right reciprocating air compressor can significantly impact the efficiency of your operations, whether you're in manufacturing, agriculture, or construction.

Understand Your Air Requirements

Before selecting a reciprocating air compressor, it's essential to understand the specific air requirements of your operations. This includes determining the volume of air needed (measured in cubic feet per minute, or CFM) and the pressure requirements (measured in pounds per square inch, or PSI). Knowing these figures is crucial as it helps ensure the compressor can handle the demands of your tools and equipment without being overworked.

If your operation requires a steady supply of air for continuous tasks, such as running pneumatic tools or spray painting equipment, a compressor with a higher CFM rating will be necessary. For applications where only short bursts of air are needed, a smaller compressor with a lower CFM may suffice. Gooddeer offers reciprocating air compressors with varying CFM and PSI specifications to cater to a wide range of operational needs, ensuring that you have the right tool for the job.

Consider the Duty Cycle

The duty cycle refers to how long the compressor can run continuously before it needs to cool down. A higher duty cycle means that the compressor can operate for longer periods without overheating. If your operation requires continuous airflow, such as in industrial manufacturing, choosing a compressor with a high duty cycle is important to prevent downtime.

Reciprocating compressors are typically designed for intermittent use, meaning they are better suited for short bursts of work. However, certain models are designed for higher duty cycles, making them suitable for more demanding, continuous tasks. Gooddeer provides reciprocating air compressors that are designed to fit different duty cycle needs, from light-duty applications to heavy-duty industrial operations.

Evaluate Compressor Size and Portability

Another important factor to consider when choosing a reciprocating air compressor is the size and portability of the unit. If your work requires mobility, such as in construction or fieldwork, a portable and compact compressor may be more suitable. Portable reciprocating air compressors are easy to move between job sites and can operate using gasoline or diesel engines, making them ideal for locations without reliable access to electricity.

On the other hand, if you need a stationary compressor for a fixed location, such as in a manufacturing facility, a larger compressor with a higher air capacity may be required. Stationary compressors are generally more efficient for long-term use and provide consistent air pressure for various industrial applications. Gooddeer offers both portable and stationary reciprocating air compressors to meet the diverse needs of industries requiring mobility or stationary solutions.

Consider the Power Source

Reciprocating air compressors are available with different power sources, such as electric, gasoline, and diesel. The choice of power source depends on the specific needs of your application. Electric compressors are commonly used in areas with easy access to electricity and are more efficient for indoor use. They are quieter, cleaner, and require less maintenance compared to gasoline or diesel-powered models.

Gasoline or diesel-powered compressors, on the other hand, are ideal for outdoor or remote operations where electricity is not available. They are generally more powerful and can run continuously for long periods, making them suitable for heavy-duty applications in construction and agriculture. Gooddeer provides reciprocating air compressors with a variety of power options to ensure that you can choose the best one based on your operational environment and needs.

Maintenance Requirements

Regular maintenance is essential to keep a reciprocating air compressor running smoothly and to extend its lifespan. When choosing a compressor, it's important to consider how easy it is to maintain and service. Reciprocating air compressors generally have a simpler design than other types, which makes them easier to maintain. Key maintenance tasks include checking oil levels, replacing filters, inspecting belts, and cleaning air intakes.

For users who are new to reciprocating compressors, choosing a model with accessible components and clear maintenance instructions can make the process easier. At Gooddeer, we provide comprehensive user manuals and after-sales support to help you maintain your reciprocating air compressor efficiently, ensuring that it operates at its best for years to come.

Noise and Vibration Considerations

Reciprocating air compressors tend to produce higher noise levels and vibrations compared to other compressor types like rotary screw compressors. This is due to the piston movement inside the cylinder. If noise is a concern in your workplace, consider selecting a model designed with noise reduction features such as enclosed housing or soundproofing materials.

In addition to noise, vibrations can also affect the compressor’s performance and longevity. To minimize vibrations, ensure that the compressor is placed on a stable surface and consider using vibration-dampening pads. Gooddeer’s reciprocating air compressors are designed with features that help reduce both noise and vibration, ensuring that your work environment remains comfortable and safe for your team.

Cost and Efficiency

When selecting a reciprocating air compressor, it is essential to balance the initial cost with long-term operating costs. While piston compressors may have a lower upfront cost compared to other types of compressors, they may be less energy-efficient in some applications. It's important to consider the efficiency of the compressor in relation to the energy costs for running it.

For businesses looking to minimize operating costs, choosing a compressor with energy-saving features, such as an automatic shut-off or pressure switch control, can help reduce electricity consumption when the compressor is not in use. Additionally, regular maintenance ensures that the compressor continues to run efficiently, preventing unnecessary energy waste. Gooddeer offers reciprocating air compressors with energy-efficient features to help businesses optimize their energy usage while maintaining performance.

Comparison of Key Features

The table below compares key features of different reciprocating air compressors, helping you choose the right model for your needs:

| Feature |

Portable Model |

Stationary Model |

| Power Source |

Gasoline, Diesel |

Electric |

| Mobility |

High |

Low |

| Noise Level |

High |

Moderate |

| Air Capacity |

Moderate |

High |

| Efficiency |

Moderate |

High |

Choosing the right reciprocating air compressor requires evaluating your specific needs based on air demand, duty cycle, power source, and maintenance requirements. At Gooddeer, we offer a wide range of reciprocating air compressors designed to meet the diverse needs of industrial, agricultural, and construction sectors. Whether you need a portable solution for fieldwork or a stationary model for large-scale operations, we can help you find the best compressor for your business.